CFD Cleanroom

SIMULAZIONI > CFD CASE

CLEANROOM DESIGN

CFD Computational Fluid Dynamics

(CFD Fluidodinamica Computazionale delle Camere Bianche)

CLENAROOM DEFINITION

Clearoom is a controlled environment with a constant, highly filtered air flow to flush out impurities such as

- micro airborne organisms

- dust

- water vapour

- other contaminants

CLEANROOM & INDUSTRY

Cleanroom facilities are necessary for activities performed in scientific/industrial applications:

- pharmaceutical

- scientific research

- electronics

- surgical rooms

- manufacturing

These industries employ clean room techniques to keep products / instruments /personnel free from contaminants.

CONTAMINANTS

Contaminating particles are dangerous

and, if cleanrooms are not designed properly,

could have negative effects inside the lab.

It's important

to provide confidence

that air quality targets are met.

ENERGY

Up to 50 times energy.

Cleanroom

vs

non-classified areas.

SAVINGS

Optimizing

efficiency

gives

financial benefits.

DESIGN

Get

things done

at

first time.

Why CFD for CLEANROOM?

Using our CFD (Computational Fluid Dynamics) engineering service as part of the cleanroom design process, you can:

- validate design performance

- optimize airflow

- check air change effectiveness

- evaluate risk of contamination

- ensure air quality targets

- control flow field and air velocity

- check energy efficiency

- analyze cleanrooms in every working scenarios

So you can ensure a better cleanroom design and meet the required performance criteria.

YOU CAN

ENSURE

a better

Cleanroom Design

MEET

the required

Performance Criteria

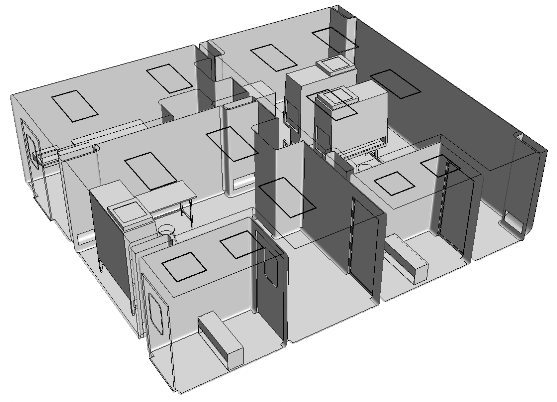

STAMINA LAB EXAMPLE

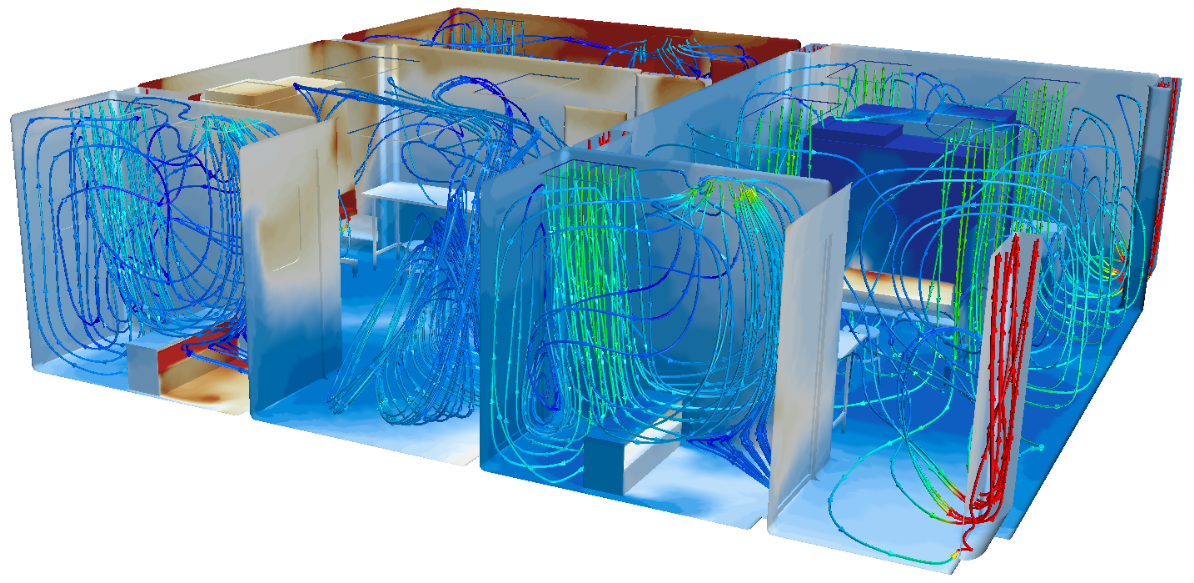

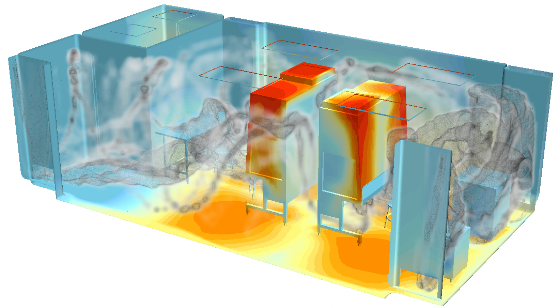

VALIDATE DESIGN PERFORMANCE

Check:

- Flow patterns and air velocity

- Air change effectiveness

- Vorticity and recirculation

You can identify zones of the cleanroom that might be troublesome.

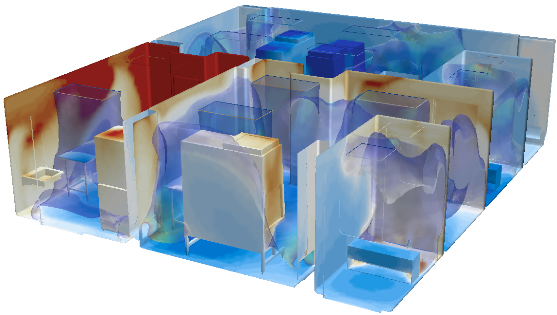

OPTIMIZE AIRFLOW

After checking flow patterns, air change effectiveness and recirculation, you can apply changes and the CFD can show the improvements in your design.

You can:

- Evaluate the air speed within the room.

- Identify areas of high flow velocity.

- Ensure steady air movement throughout the whole domain.

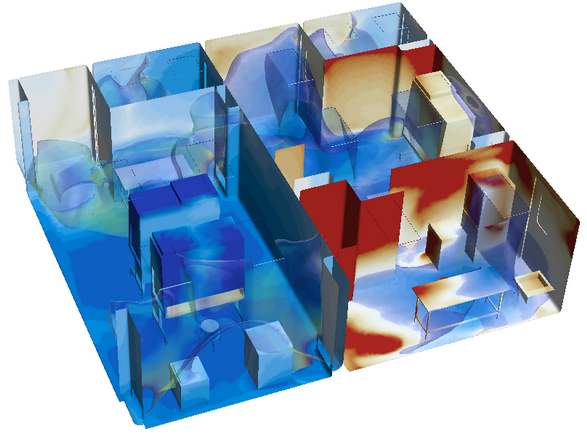

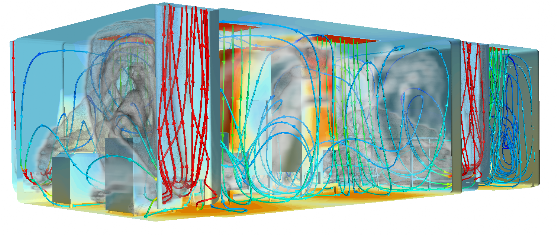

CONTAMINANTS

Contaminant control is important: CFD can predict distribution and concentration in the cleanroom.

Tracking contaminants will allow a greater control over potential hazards.

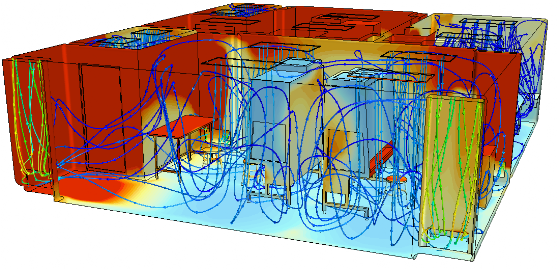

PURGE TIME

CFD allows to calculate the time required to remove all contaminants from the cleanroom.

With this simulation focus, you can identify zones where contaminats could be more persistant.

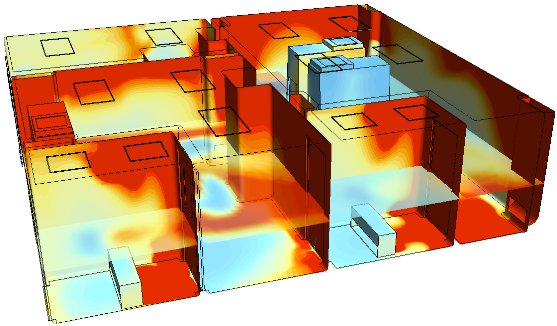

MULTI-OPERATION STATE ANALYSIS

Cleanroom state changes continuosly.

Opening a door, personnel moving, switching on a device can influence the state of the cleanroom.

CFD can analyze the performance in different working scenarios.

All conditions should be investigated and verified for ensuring your best-in-class design.

ENERGY EFFICIENCY

CFD allows you to analyze:

- temperature distribution

- cooling / heating performance

- steady operational conditions

- comfort conditions for personnel

Please don’t hesitate to get in touch.

We will be happy to assist with your enquiry.

We will be happy to assist with your enquiry.

This form is anonymous,

unless you decide to insert your personal data.

If you want a direct contact,

please remeber to insert your email.

If you wish,

we'll send you the preview of the new post.

Be the first to get informed!